STATION WITH FULL INTERNAL POWER CONSUMPTION).

INTRODUCTION.

The project is developed by the group of experts in the

field of biotechnologies. The present project represents innovative

agro-industrial complex “Simbioz”. A placement of the complex is planned for

the territories of Mordovia in the Kovylkinsky area.

The organization of waste-free production with completion

and economy of energy consumption is planned there. By-products of a livestock

farm, a goat farm, a hothouse complex, will be used for producing energy and

getting accompanying types of agricultural production. All products of the complex

are led up to a stage of the ready consumer-oriented goods. At design of the

complex the modern technologies were used, which allow to cut down both

starting and current expenses, and also to construct symbiosis of animals, fish

and plants.

The by-product – manure - will be used for getting energy

(a biopower complex), a biohumus, with application of technology of the

Californian worms container cultivation. Manure and waste recycling to ready

fertilizers allows supplying a hothouse of 20 hectares with fertilizers

completely, and cultivation of the Californian worm will allow us to meet the

needs of fishery (sturgeon breeding) for live feed, with annual capacity of

1000 tons of fish and 40 tons of black caviar. Plant residues of vegetable

products such as germinated grain and beans will be used as the main feed of livestock

farms, and also for baking of dietary protein-rich bread.

Based on logistics, the project is subdivided into blocks:

1) production of livestock products by deep processing of dairy and meat

products; 2) cultivation and production of forage (a formula-feed plant or a

feed-milling plant) and fertilizers; 3) processing and packing of finished

goods; 3) building of workers’ villages; 4) plant growing and fish breeding; 5)

power block.

It is planned to build a cottage settlement in 3000 houses

on 120 sq. m for involvement of experts and highly qualified personnel.

Total area: 120,4 sq.m.

Examples of facades for various constructive decisions and

styles are given below.

Project of a cottage 1

Foundation: precast concrete

External walls: cellular concrete

Ceilings: on wooden joists

Covering: bituminous tile

External finishing: front brick or plaster

Total area: 120,4 sq.m.

The architecture of this cottage is focused on high comfort at the minimum construction costs.

Project of cottage 2

Foundation: monolithic concrete

External walls: cellular concrete

Ceilings: on wooden joists

Roof: with the attic

Covering: metal tile

External finishing: facing brick, vinyl lining

A ground floor: natural stone

Total area: 120,1 sq.m

Living space: 50,4 sq.m.

Project of cottage 3

Foundation: monolithic concrete

External walls: cellular concrete

Ceilings: on wooden joists

Roof: a curb roof

Covering: metal tile

External finishing: vinyl lining

A ground floor: natural stone

Total area: 120,1 sq.m

The project will help to create about 2800 workplaces.

2. PURPOSE OF THE ORGANIZATION OF THE COMPLEX.

The project of a complex farm is realized for providing the population with meat and dairy products, fish, and high-protein vegetable products, implementation of scientific development of the FSUE RFNC-VNIIEF, Sarov city of the Nizhny Novgorod region, FSUE VNIIPRKH, Dmitrov of the Moscow region, VNIMI, creation of workplaces, economic development of the Kovylkinsky area. After the technology is worked out on this complex, we are planning to build the second module of agro-industrial complex on other territories of the Russian Federation. Besides, energy saving technologies will be implemented, and alternative power supplies will be used. Introduction of new technologies and symbiosis of animals, fish and plants will allow us to reduce prime cost of agricultural production.

3 . IDEOLOGY OF THE INVESTMENT PROJECT.

Agro-industrial policy of the RF determines strategic goals in the long-term program of agriculture development as following:

• in economic area - formation of the effective competitive agro-industrial production ensuring food safety and independence of the country, export increase of separate types of agricultural products, increase in a contribution of agro-industrial complexes to the national economy;

• in social area - gap overcoming in a standard of living and social security between country and urban population;

• in ecological area - production of ecologically pure products and creation of ecologically safe conditions for the population, fauna and flora, preservation of natural resources for agrarian production.

4 . THE DESCRIPTION OF PRODUCTION.

4.1 . livestock products:

1 . Milk 0,5; 1l in polyethylene package.

2 . Packaged sour cream.

3 . Exotic cheese (with use of fish production).

4 . Adygei cheese.

5 . Meat products: cooled veal , fresh-frozen veal ,smoking, cutting e.t.c.

6 . In the long term production of leather goods.

4.2 . Fish breeding production:

1 . Live fish of sturgeon breeds.

2 . Fresh-frozen fish.

3 . Sturgeon of hot and cold smoking.

4 . Different types of cuttings, in the long term products from sturgeons’ skin, and also extract from sturgeon milts which is used in medicine production.

5 . The black caviar packaged in glass jars on 56,8 g (2 oz) and 113,6 g (4 oz).

4.3 . Production of a hothouse complex and vegetable functional products:

1 . Functional drinks from germinated soy, wheat, oats more than 5 g. Protein in 10 grams in

package Tetra-Brick, polyethylene, glass, Pure-PAK. Drinks, tea with vegetable adaptogen and

herbs in polyethylene-bottles of 0,5 and 1 l.

2 . Oxygen cocktails, with plant extracts in polyethelene-bottles of 0,5 and 1 l.

3 . Fresh tomatoes, cucumbers, strawberries.

4 . Canned vegetables, 500-800 g.

4.4 . Ancillary production:

Ancillary production will be made, generally, for covering the needs of the "complex farm" project.

1 . Production of heat, the electric power (a steam-gas plant), carbonic acid for top dressing of

plants and refrigeration on the local gas-thermoelectric power station combined with a biopower

complex. The biopower complex makes biogas from which methane for the gas-thermoelectric

power station and carbonic acid for production of drinks is emitted.

2 . Cultivation and production of forages: grain cultivation (wheat, barley) for compound feed

production, and also corn sowing for silo storage; storage and production of hay.

3 . Production of humus and fertilizers from manure in a biopower complex for a hothouse complex.

4 . Cultivation of the Californian worm on manure.

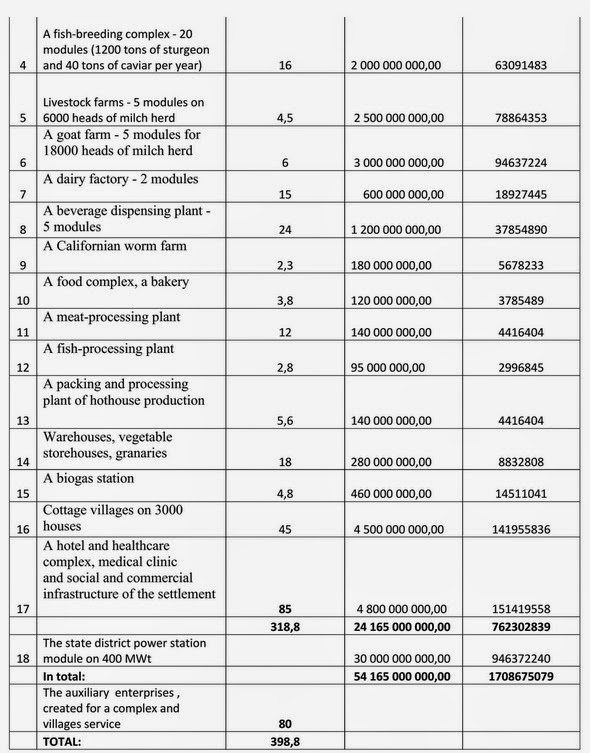

5. THE PROGECT STRUCTURE.

6. THE POWERCOMPLEX.

A project of the first module of the Combined Heat & Power Station “A STEAM-GAS

PLANT ”(CHPS SGP).

The JSC “Poisk” group of companies realizes the project on power plant construction with the combined steam-gas cycle.

The general contractor - JSC "GEK".

Suppliers of the main equipment:

• a gas turbine PG6111FA - "General Electric";

• a copper utilizer of two pressure - JSC "Podolsk Machine-Building Plant";

• steam-turbine plant with adjustable heating selection like T-25/33-7,6/0,12 - JSC "Kaluga

Turbine Plant".

The CHPS SGP will be built in four stages:

• the 1st phase of construction – the main building, the main and support equipment of the

power unit No. 1 with all accessory buildings and necessary systems for its full functioning.

The term of commissioning March, 2015.

• the 2nd phase of construction – the main building, the main and support equipment of the

power unit No. 2 with all accessory buildings and necessary systems

The term of commissioning March, 2016.the 3rd phase of construction – the main building, the main and support equipment of the

power unit No. 3 with all accessory buildings and necessary systems The term of commissioning March, 2017.

The 4th phase of construction – the main building, the main and support equipment of thepower unit No. 4 with all accessory buildings and necessary systems The term of commissioning March, 2018

The general capacity of the first CHPS SGP module is 400 MW.

Efficiency of CHPS SGP heating blocks (average annual efficiency of fuel heat) — 76,9%.

CHPS SGP represents the independent power plant joint to power supply of agro-industrial complex, workers' villages and social and commercial infrastructure, and also with additional constructions and communications.

The new CHPS SGP is the main source of thermal and electric energy.

It is constructed to supply the agro-industrial complex and other objects of settlements with power and heat for the period till 2018 with development prospect till 2025.

The main fuel of the SGP blocks – natural gas. Emergency and reserve fuel isn't provided.

The installation of four power units of CHPS SGP is provided.

The thermal scheme provides possibility of operation of each block of station in the following main modes:

- in a heating mode (during the heating period) with the heat supply of the heating system;-in a condensation mode (during the non- heating period) with the heat supply to 25 Gcal/h from each block;

-with the steam supply for production needs (to 30 h/h).

Construction of the power station has extremely important value for providing agro-industrial complex "Simbioz" with electric and thermal energy.

The planned number of the personnel.

The total number of the personnel the SGP is 292 people.

The total number of the personnel the SGP is 292 people.

The payback period is less than 5 years from the start-up of the complex .